These days, there are many different types of printing methods available, some that you might not even have heard of. And as they continue to evolve, the projects that different printing technologies are suited for continues to grow. That being said, each type has generally been developed with a specific task in mind and it is thus still important to do your research.

As a business owner, or promotional coordination, you can choose a printing technique that best highlights the products or service you have on offer. Here is a rundown of some of the best new printing technology methods and what they have to offer.

1. Digital printing technology

Most people are familiar with digital printing, but this new printing technology has seen many advanced developments. Digital images can now be reproduced on physical surfaces like cloth, plastic, magnets, labels, cardboard, film etc. Done by both industrial and desktop printers, with this kind of printing it is not necessary to keep yourself confined to single or two colours.

The only thing you really need to be aware of here is that digital Printing asks for an image resolution of 300dpi, if the quality of image is any lower than that, you won’t be able to ensure the value of the final product.

2. Screen printing technology

Once confined to only silk materials, screen printing is now more widely accessible on a variety of materials. With the ability to use a variety of brightly colored inks, screen printing is often used for printing posters, t-shirts and other promotional items.

In order to complete the process, the design is laid on the top of the screen then covered with photo emulsion and exposed to light. It is thanks to exposure to heat that the emulsion is prompted to become hard, after which the rest is washed away, leaving behind a one of a kind stencil.

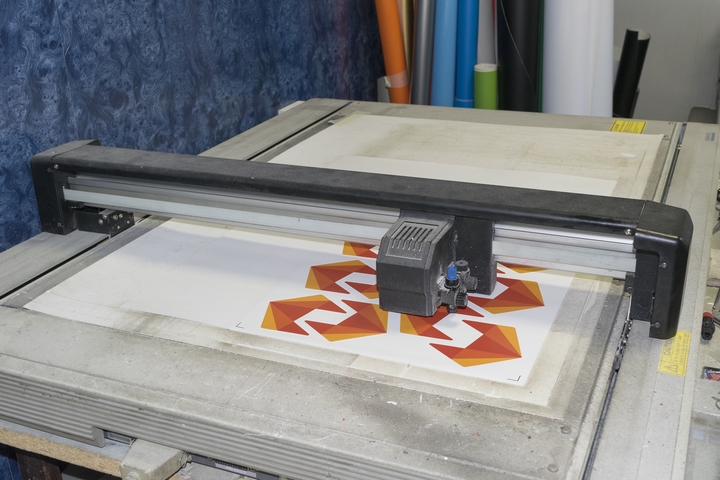

3. Flexography printing technology

Flexography has become increasing popular in recent years, since the new printing technology behind it has been refined and perfected. flexography is usually operated using web presses which prints on long and continuous rolls of paper. The paper is kept organized via flexo storage solutions, which will preserve the quality and condition of the paper.

Flexography also has the advantage of using water-based inks and rubber plates which dry very quickly and facilitate fat production rates. Flexography has an interested history and although it is essentially a modern version of letterpress, it can now be used for printing on almost any type of substrate. This includes various types of plastic, metallic films, cellophane, and paper.

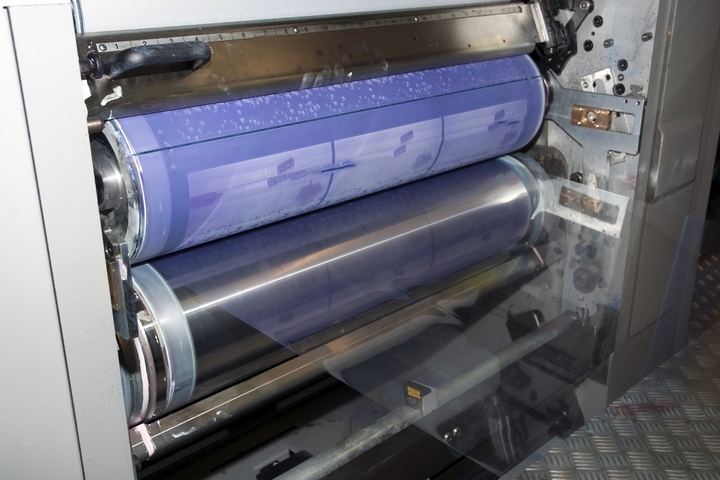

4. Litho printing technology

Not unlike digital printing mentioned above, litho printing is ideal for creating full colour prints on different types of physical surfaces. It is a fairly accessible and widely available method that also allows one to create personalized promotional products that will continue over multiple printing runs.

Like digital printing technology, you need a resolution of at least 300dpi to use this method of printing successfully.

5. Transfer printing technology

A clever innovation in printing that allows images to be applied to curved or uneven surfaces, transfer printing is mostly used for printing on materials like porcelain and cloth like surfaces. Transfer printing requires high-resolution images with vector in order to be applied on a range or products.

6. Engraving technology

Generally considered the costliest of the various printing methods available, engraving is also a fairly time-consuming endeavour. Imagine the impeccable quality of royal invitation cards or the business cards of high-ranking officials, these are cases in which you’re likely to see engraving being used.

Traditionally, the primary image is engraved by a hand or machine on a metal plate, then it is filled in with ink and a paper is pressed on it. Due to this unique process, a three-dimensional element, which is almost impossible to accomplish with other methods, can be obtained.

7. Embossing technology

In the process of embossing, an impression of the design is created on a surface of the product. This is accomplished by applying a predetermined amount of pressure in order to create the mark on the design on the object.

Once the impression has been made, the pressure is released. Embossing can be done in two different ways. There is bling embossing in which the embossed mark is of the colour of the product itself or foil block embossing, which, after the initial design is embossed, it is filled with metallic paints like silver and gold.

8. Embroider printing technology

A delicate and precise method or printing, embroidery printing allows artworks to be recreated by decorating fabric with designs that are stitched in strands of thread with a needle. A fairly complex procedure, a special printing machine is required in order to produce embroidered printing on a larger scale.

Due to the need to operate from colour references that will try to match different hues from the samples provided, it is best to avoid using too much variety when selecting the colours that will be used.